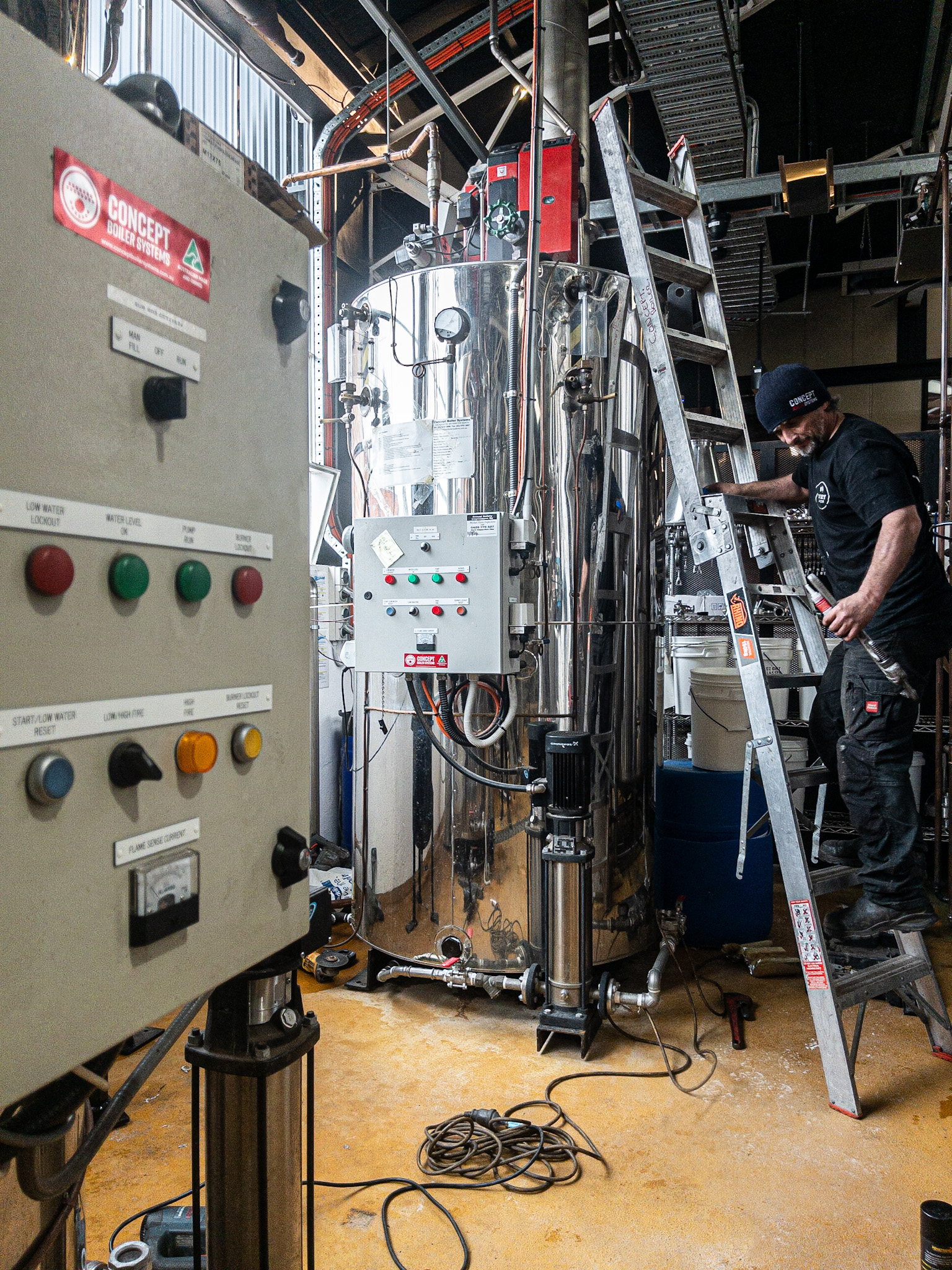

Installing Boiler Systems at Australia's Best Craft Breweries

With Australia's best Craft Breweries using Concept Boiler Systems for steam jacket heating, we are Australia's most recognized name in Craft Brewery Boiler Systems.

Our team has extensive experience in the manufacturing and installation of Steam Boilers for Craft Breweries. We are experts in brewhouse hookups, CO2/Filtered Water and Glycol line installation. Our pipe work installations are neat and highly functional, a key requirement for Craft Breweries with publicly visible installations. We've got a thorough appreciation for the product, culture and industry, making us the clear choice for Craft Brewery Boiler Systems in Australia.

Talk to Concept today to find out about the best steam solution for your Craft Brewery.

The Best Boiler System for Brewhouse Hookups

We are the most experienced Craft Brewery Boiler System manufacturer in Australia. With a complete system that's designed and built for efficiency and sustainable production, our Boiler System will ensure your brewing operations are consistent and reliable year round.

The primary benefit of using steam to heat your brewhouse is the enhanced efficiency it provides when heating the water used for mashing, sparging and boiling. When you fit our advanced condensate capture system to your brewhouse, you can recycle the heated water and increase sustainability even more by recycling the heated condensate back into the boiler system - resulting in faster boil times and reduced energy usage.

With experience building and fitting valve trains in small and large breweries, installing custom made steam line and providing food grade, stainless steel piped culinary steam for keg washing and barrel ageing, we are the go-to craft beer steam experts.

Custom Steam Line and Pipe

We assess, design and manufacture all your pipework on site to fit your brewery layout perfectly. Our team's approach maximizes your available brew floor space and ensures optimal steam and services delivery.

Built For Your Brewhouse

Our Watertube Steam Boilers can be build in sizes from five to fifty horsepower, maximizing efficiency for your brewing processes and providing cost-effective scaling in the future.

Australian Made Quality, Competitive Pricing

Our range is exclusively Made in Australia for shorter lead times, superior quality and far lower environemntal impact

"We rely on our boiler to operate all day, every day and the machine we have from the guys at Concept has not missed a beat.

"You can buy a cheaper imported boiler but you can’t beat the Australian made, built to last workmanship that these guys deliver."

The Best Steam Boiler for Craft Breweries in Australia

Benefits of Steam Boilers for Brewing

Water Tube Boiler Design

Steam produced with a gas fired boiler delivers a more efficient mash process than electric elements or gas burners on the brewhouse. Using Steam Boilers can save money and significantly reduce your environmental impact through more efficient energy use.

High-Quality Fit & Finish

Less Water, More Surface Area

High Quality Steam Boilers That Local Businesses Can Afford

Australian Made, Competitive Pricing

Concept Boiler Systems been building Steam Boilers in Bayswater North for over twenty years. We've built relationships with Melbourne's best trades, suppliers and logistics teams, and invested heavily into our team of dedicated boilermakers, service technicians and designers.

We've worked hard to keep our Australian-Made products competitive - and that means our customers enjoy faster lead times, market-leading quality and the best customer service in the market - all while keeping their projects on-budget.

Comparable Pricing

Our quality Australian Made boiler systems are available at similar price points to imported Steam Boilers.Built to Australian Standards

We don't cut corners. Our Steam Boilers are built in Australia to stringent safety standards.Personalized Service

You'll deal with the same team who manufactures the systems and benefit from a wealth of expert knowledge.In-House Trades, Trusted Partnerships

Mechanical Services

By maintaining an extensive network of mechanical services trades and suppliers, we ensure quality and consistency while keeping lead times to a minimum.Electrical & Data

We take safety seriously - that's why the switchboards and circuits that co-ordinate the Burner, Pumps and Alert Systems of the are hand-wired in Bayswater.Transport & Logistics

Because we manufacture locally, we aren't affected by shipping delays, customs inspections or supplier capacity that other boiler manufacturers encounter.CAD Design & Simulation

Our qualified boilermakers work alongside our in-house design team to draft, test and perfect our products. Every boiler is precision built to perform efficiently and to specification.